Overiew of all currently available interfaces. The portfolio of supported systems is continuously increasing and steadily extended by new developments.

We do not host any torrent files or links of Aplikasi Bbm Untuk Laptop from depositfiles.com, rapidshare.com, any file sharing sites. Download aplikasi wifi untuk laptop. All download links are direct full download from publisher sites or their selected mirrors.

Mission: Impossible - Ghost Protocol (2011) 2011 (tt1229238) In the fourth installment of the Mission Impossible series, Ethan Hunt and a new team race against. .png)

This software modul enables you to integrate Honeywell Fire panels Esser IQ8 or Esser FlexES into Niagara AX based controlers called Centra Line HAWK. Home Business Fire Alarm Systems ESSER by Honeywell Products Control Panels IQ8Control Panels Accessories IQ8 Control Maintenance and Test. Centrale Rilevazioni Incendi Esser. If necessary, the control panel software can simply be replaced by an upgrade version via a service PC. IQ8 Control IQ8.

General Alarm Systems

- ABI – MC1500

- Bosch – UGM 2005 / 2010 / 2020

- Esser (Honeywell) – BMZ 8000 via SEI

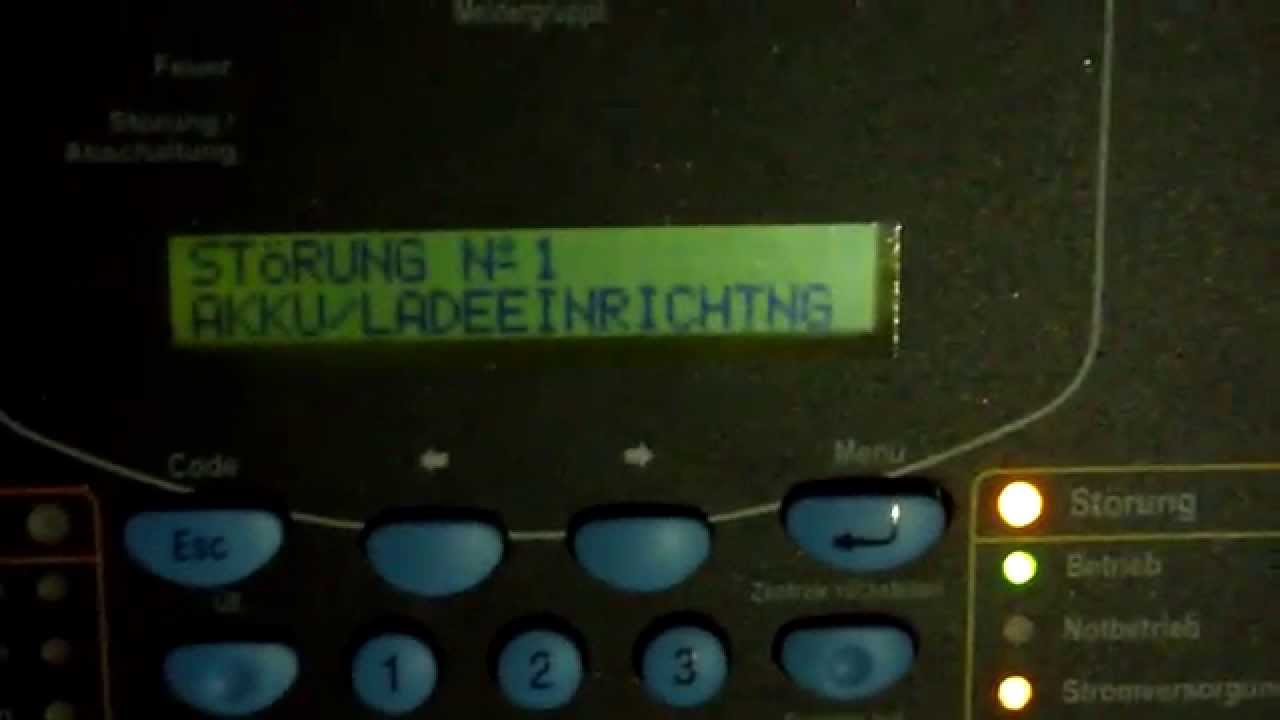

- Esser (Honeywell) – BMZ IQ8 Control via SEI

- Securiton – SecuriPro

- Siemens – SM80

- Siemens – SM88 (SM-PORT, FRK, FRK-B)

To optimize our website, we use Google Analytics for evaluation of anonymous user data. Further information can be found in our Privacy Policy.

Privacy Overview

This website uses cookies so that we can provide you with the best user experience possible. Full version minecraft. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Advertisement

Related Manuals for Honeywell IQ8Control C

- Control Panel Honeywell Galaxy 16 User ManualHoneywell security system user guide (30 pages)

- Control Panel Honeywell Galaxy 3-48C Installation Manual(90 pages)

- Control Panel Honeywell GX-Series Installation And Setup ManualGx series; (208 pages)

- Control Panel Honeywell T631A-C FARM-O-Stat User ManualFarm-o-stat airswitch controller (5 pages)

- Control Panel Honeywell TrueZONE HZ311 Installation ManualZone panel professional installation guide (12 pages)

- Control Panel Honeywell Galaxy 2 Series User ManualProgrammable alarm control panel (20 pages)

- Control Panel Honeywell TrolaTemp MABS EZ-2 Product DataMastertrol automatic balancing system control panel (12 pages)

Remote Control Software

Summary of Contents for Honeywell IQ8Control C

- Page 1 Installation Instruction Fire Alarm Control Panel IQ8Control C/M 798951.GB0 G 299044 Technical changes reserved! 01.2009 G 205129 © 2009 Honeywell International Inc.

- Page 2 Fire Alarm Control Panel IQ8Control C/M Intended purpose This product must only be used for the applications outlined in the catalogue and the technical description and in combination with external components and systems which have been approved or recommended by Esser by Honeywell.

Page 3: Table Of Contents

Fire Alarm Control Panel IQ8Control C/M Installation Instruction...............5 System overview................ 7 Configuration options ...............8 Special configuration – Swiss option ...........9 FACP IQ8Control C..............10 FACP IQ8Control M..............12 Definition of the Primary loop number...........17 Central housing...............19 Assembly................- Page 4 Fire Alarm Control Panel IQ8Control C/M Master box activation module .............87 Technical Data Master box activation module (Part No. 784385) .......91 Installer level................96 Diagnostic display ...............108 Diagnostic display IQ8Control C/M ............ 108 Meaning of the three digit error codes / test mode..........115 Functionality for fire alarm control panels...........

Page 5: Installation Instruction

Fire Alarm Control Panel IQ8Control C/M Installation Instruction Operation of the Fire Alarm Control Panel IQ8Control is governed by the national version of the operating system software used and the country version programmed in the customer data. The terminal assignment and..- Page 6 Fire Alarm Control Panel IQ8Control C/M Standards and guidelines The general technical rules must be observed when installing fire alarm systems. Any deviation from those rules is only admissible if the same degree of safety can be ensured with different means. Installations within the European Community are primarily subject to all EU regulations defining the current standards for security systems.

Page 7: System Overview

The modular design with different micro modules and individual extension concepts allow the Fire Alarm Computer IQ8Control C and IQ8Control M to be easily adapted to special requirements. This provides the range from a stand-alone panel up to 31 Fire Alarm Control Panels Computer or other network subscribers such as supervising system WINMAG, Fire department indicator panel or Intruder Alarm Panels Series 5000 by using ®..Page 8: Configuration Options

Fire Alarm Control Panel IQ8Control C/M Configuration options The operating module front (7860xx) is available in various language versions. The language is defined with the 2-digits of the part number, e.g. 786002 = English lettering. IQ8Control C IQ8Control M Operating module..Page 9: Special Configuration - Swiss Option Ch

786261 786262 786263 Fig. 3: Operating module – Swiss with integrated Fire department operating panel (FBA) For country-specific displays and labels as well as further information refer to operating instructions FACP IQ8Control C/M (Part No. 798950.GB0). FB 798951.GB0 / 01.09..Page 10: Facp Iq8control C

On the Basic module only the upper slot (slot 1) of can be used for a Field device or Extension module. The lower slot (slot 2) of the FACP IQ8Control C is not used. Micro module Power supply module Part No.- Page 11 Fire Alarm Control Panel IQ8Control C/M Configuration of FACP IQ8Control C MM 1 Example 1: Basic module with a micro module and a Field device module (Part No.772479 without micro module slot) on slot 1 of the Basic module. Application: With this configuration, for example, a single control panel with an analog loop and max.

Page 12: Facp Iq8control M

Fire Alarm Control Panel IQ8Control C/M FACP IQ8Control M The configuration of the FACP IQ8Control C includes: • 1 Basic module • 1 Power supply module • 1 Field device module or 1 Extension module 1 • max. 2 Extension modules - each with three micro..- Page 13 Fire Alarm Control Panel IQ8Control C/M Example: Configuration of FACP IQ8Control M Example 1: Basic module with a Field device module MM 1 (without micro module slot) on slot 1 and one MM 4 Extension module (with 3 micro module slots) on slot 2.

- Page 14 Fire Alarm Control Panel IQ8Control C/M Example: Configuration of FACP IQ8Control M Example 3: Basic module with a Field device module (without micro module slot) on slot 1 and MM 2 one Extension module (with 3 micro module slots) on slot 2.

- Page 15 Fire Alarm Control Panel IQ8Control C/M Three part housing with integrated printer The integrated printer and the operating module front are mounted in the upper housing. Due to the depth of the printer, the Basic module and all of the plug-in cards are integrated into a separate housing beneath. The emergency power supply with max.

- Page 16 Fire Alarm Control Panel IQ8Control C/M Location of the components in a three part FACP housing IQ8Control M Fig. 11: Location of the components in a three part housing Mounting plate for master boxes DS 7500 / DS 8800 ®..

Page 17: Definition Of The Primary Loop Number

Fire Alarm Control Panel IQ8Control C/M Definition of the Primary loop number Individual assemblies of the FACP IQ8Control can be switched on/off with the internal primary loop number through the control panel keyboard or programmed with programming software . This internal primary loop number is composed of the control panel number, the slot and the assembly number.- Page 18 Micro module slot 2 0133 Micro module slot 3 The Field device module (if available) must be installed in >Slot 1< of the Basic module. >Slot 2< of the Basic module is unused on the FACP IQ8Control C. FB 798951.GB0 / 01.09..

Page 19: Central Housing

The three unused fastening points between the base plate and the housing frame are not necessary on the FACP IQ8Control C/M. This fastening is intended for a different housing use. Danger - Electrical shock ! Disconnect all power from the panel before carrying out any installation work. The panel may only be operated while the cabinet is closed.Page 20: Assembly

Fire Alarm Control Panel IQ8Control C/M Assembly The housing is pre-assembled by factory delivery. To ease the further assembling and mounting please observe the given mounting sequence. Fig. 14: Exploded illustration 4x wall compensation pieces 1 x Metal sheet of the base plate for shielding and the PE connection (functional earth)- Page 21 Fire Alarm Control Panel IQ8Control C/M Operating module / Housing door The operating module/the housing door is installed by the manufacturer on the front housing part. If required for dismantling, loosen the 4 fixing screws and remove the front part of the housing.

- Page 22 Fire Alarm Control Panel IQ8Control C/M Housing contact The housing contact provides the monitoring of the panels housing and may be used additionally for control function by means of service or maintenance work, e.g. to disconnect devices whilst the contact is open.

- Page 23 Fire Alarm Control Panel IQ8Control C/M Connection between the central housing and the extension housing 2x connection pieces with cable glands 1. Remove the appropriate 2 plastic plates from panels and extension housing 2. Push the plastic connector bracket in each originated gap.

- Page 24 Fire Alarm Control Panel IQ8Control C/M Wall mounting The panel must be mounted on a flat surface using appropriate hardware (screws and dowels). Avoid mechanical stressing. It may only be commissioned after correct mounting on a wall or other mounting surface of sufficient strength to support the weight of the unit.

Page 25: Cable Glands

Fire Alarm Control Panel IQ8Control C/M Cable glands Lead the 230V main power cord through the wall and the cable entry provided in the rear of the unit (see illustration). Fasten it using appropriate devices, e.g. plastic cable straps. Make sure that the mains and signal cables don’t interfere with the rear panel of the cabinet or the cabinet frame which is mounted on the rear panel.Page 26: Module

Fire Alarm Control Panel IQ8Control C/M Module The FACP IQ8Control C / M has a modular design so that modules can be replaced/extended at any time. Only remove or insert modules when the FACP is voltage free. • Switch off the power and battery supply.- Page 27 Fire Alarm Control Panel IQ8Control C/M Earth fault monitoring BR 1 1 2 3 Earth fault monitoring enabled (factory default = ON) 1 2 3 Earth fault monitoring disabled (not VdS appropriate) Information for powered loop systems In case of an earth fault with +U..

Page 28: Mains Connection And Earth Connections

Fire Alarm Control Panel IQ8Control C/M 4.1.1 Mains connection and earth connections Housing mantle T1.25A terminal H/230V~ Main 230V~ Cable corss section at least > 4mm² to PE rail Fig. 22: Connection of the rated voltage (230 V AC) and earth connections on the basic module The mains supply must be installed in accordance with local regulations by a qualified technician.Page 29: Protective And Functional Earth

The base module is connected to the rear panel of the cabinet by means of metal spacers and screws. This electrically conducting connection between base module and rear panel is essential for correct functional earthing of the FACP IQ8Control C/M. FB 798951.GB0 / 01.09..Page 30: Emergency Power Supply

< 10,0V DC) will not charge correctly! battery Only the battery types approved by the Esser by Honeywell Fire Alarm Control Panel may be used for supplying the Fire Alarm Control Panels with backup power. Observe the information and technical specifications of the battery manufacturer and the VdS-guidelines for deep charged batteries.- Page 31 Fire Alarm Control Panel IQ8Control C/M Connection of two batteries Battery 1 Battery 1 Battery 2 Battery 2 F2 battery 1 F3 battery 2 T2.5A T2.5A Fig. 24: Connection of two batteries Battery 1 max. 12 V DC / 24 Ah Battery 2 max.

- Page 32 Fix the mechanical battery fastener by inserting the two screws Fig. 26: Mechanical battery fasteners e.g. compact housing IQ8Control C Up to 2 batteries 12 V / 24 Ah may be placed inside the lower housing part of the IQ8 Control M or in the extension housing (part no.

Page 33: Specification Power Supply Module (part No. 802426)

PLus) must be selected on the power supply module with jumper BR4! For IQ8Control C/M fire alarm control panels it is possible to use the power supply module from hardware version Index G as a replacement module. Pay attention to the settings on the power..Page 34: Basic Module

Fire Alarm Control Panel IQ8Control C/M Basic module The power supply module and a free selectable micro module may be installed on the appropriate Basic module connectors. >System connector 1< provides the connection of a Field device module or Extension module.- Page 35 Fire Alarm Control Panel IQ8Control C/M Solder jumper to set whether the two batteries are connected and the monitoring for the free battery connection should be switched off. Open (default) Connection of two batteries >Battery 1+2< closed Connection of a single battery only to connector >Battery 1<.

- Page 36 Fire Alarm Control Panel IQ8Control C/M Connection of the AC mains voltage and batteries The AC mains voltage must be connected to this terminals of the Basic module. Refer to section “power supply module” for detailed information. Mains 230V~ Fig. 29: Connection of the AC mains voltage and batteries..

Page 37: Software

Fire Alarm Control Panel IQ8Control C/M Software System requirements: Firmware: Version V3.01R000 or higher Programming software tools 8000: Version V1.06R001 or higher 4.3.1 Firmware Update The system software (Firmware) of the FACP IQ8Control may be updated directly at the panel via the integrated USB interface.- Page 38 Fire Alarm Control Panel IQ8Control C/M Open panel housing Set DIL switch S2 (1+2) on the Basic module in Pos. ON (LED V50 lits). Press reset button FACP reset Wait until FACP is resetted and the display message „Servicemode“ appears.

Page 39: Customer Data Programming

Fire Alarm Control Panel IQ8Control C/M 4.3.2 Customer data programming The Fieldbus- und panel interface (Part No. 789863) or panel interface (Part No. 769828) is required to configure the panels Customer data. The software tools 8000 from Version V1.06 provides the configuration of the FACP IQ8Control functions and customizing the system to all requirements.Page 40: Housing Contact

Fire Alarm Control Panel IQ8Control C/M 4.3.3 Housing contact Housing open X7 X8 Depending on the panel housing used, up to four cover contacts can be connected to the connection terminals of the Basic module. A single contact per housing is integrated by factory settings.Page 41: Serial Interface

Fire Alarm Control Panel IQ8Control C/M 4.3.4 Serial interface The serial interface on the Basic module may be configured as a TTY interface (20 mA) or as an RS485 interface. The required interface to connect external devices is selected by the Service software tools 8000 from Version V1.06.- Page 42 Fire Alarm Control Panel IQ8Control C/M RS485 interface An external device, such as an LCD display panel, can be connected to the A/B terminals via the RS485 interface. • The RS485 BUS must be connected with an EOL resistor at both ends of the loop.

- Page 43 Fire Alarm Control Panel IQ8Control C/M Common trouble relay Contact change-over (EMI protected) Breaking capacity : 30 V DC / 1A Function Common trouble (SaS-relay FAULT) SaS-Relay If the control panel detects at least one trouble incident, relay activation will be interrupted and the relay will change its control status.

Page 44: Micro Module Slot

Fire Alarm Control Panel IQ8Control C/M 4.3.5 Micro module slot Eight connection terminals are provided at the micro module slot on the Basic module for connecting the freely selectable micro module. Assignment of the eight screw terminals will depend on the micro module type used.Page 45: Technical Data Basic Module

Part No. 772482 Basic module IQ8Control M The Basic module is suited for the Fire Alarm Control Panels IQ8Control C/M with the required power supply module (Part No. 802426 from index G). ® The required loop voltage (27,5 V or 42 V for esserbus PLus) must be selected on the power supply module.- Page 46 Fire Alarm Control Panel IQ8Control C/M Field device module The Field device module required in order to configure a stand-alone FACP in accordance to the appropriate standards and guidelines. The Field device module integrates all of the input and output modules that are necessary in addition to the modules on the Basic module to operate as a Fire Alarm Control Panel to DIN VDE 0833.

- Page 47 Fire Alarm Control Panel IQ8Control C/M Field device module (Part No.772479) without micro module slot Field device module Fig. 40:Field device module (Part No.772479) Field device module (Part No.772477) with micro module slot Field device module Fig. 41: Field device module (Part No.772477) The Field device module (if available) must always be placed on the >System connector 1<..

- Page 48 Fire Alarm Control Panel IQ8Control C/M Relay for connecting a master box. May also be used as a freely programmable relay. Relay K1 Selection of operating mode and emergency function by means of jumpers. (Monitoring range 50 Ω to 1 k Ω ) Contact rating when used as a >non-monitored change-over contact<..

- Page 49 Fire Alarm Control Panel IQ8Control C/M Connection terminals Screw terminal: removable, Connection terminals max. 1.5mm IN - top removable OUT - bottom removable Fig.42: Connection terminals Connection terminals fire department operating panel Connection of the micro module Eight connecting terminals are provided for the micro module slot of the Field device module. The actual connection of the eight terminals depends on the type of module used.

Page 50: Connecting A Fire Department Operating Panel

Fire Alarm Control Panel IQ8Control C/M 4.3.7 Connecting a fire department operating panel • Wiring differs from area to area and is governed by the requirements of the bottom - terminals regional fire department. • top - terminals A 12 V DC voltage is required for operation.Page 51: Connecting The Master Box (relay K1)

Fire Alarm Control Panel IQ8Control C/M 4.3.8 Connecting the master box (Relay K1) Relay K1 for the connection of a master box is part of the peripheral module. The control configuration of relay K1 can be set to • monitored and switching the positive potential •..- Page 52 Fire Alarm Control Panel IQ8Control C/M Operating mode 1 Relay K1 positive switching and monitored Fig. 46: Terminal of the master box relay K1 Relay K1 positive switching (+12 V DC / max. 1A) and monitored intern Monitored end-of-line resistor R = 680 Ω (factory setting) Monitoring capability of internal resistor in master box 50 to 1000 Ω..

- Page 53 Fire Alarm Control Panel IQ8Control C/M Wiring example: Operating mode 1 Relay K1 – positive switching and monitored FACP IQ8 Control C/M Master box Field device module (schematic circuit diagram) BACK MFAB acknowledge acknowledge ÜE - alarm ÜE + 680Ω..

- Page 54 Fire Alarm Control Panel IQ8Control C/M Operating mode 2 Relay K1 positive switching, not monitored Relay K1 Positive switching (+12 V DC / max. intern 1A), not monitored Fig. 48: Terminal of the master box relay K1 Operating mode 3..

Page 55: Connecting The Relays K2, K3, K4

Fire Alarm Control Panel IQ8Control C/M 4.3.9 Connecting the Relays K2, K3, K4 Location of the relay K2,K3,K4 and the jumpers BR9 to 20 on the Field device module Jumpers are used for adjusting the three relays K2, K3 and K4 to a variety of requirements.- Page 56 Fire Alarm Control Panel IQ8Control C/M CPU failure mode function of relays K2, K3 and K4 Fig.51: Location of the emergency mode jumpers BR3 to 5 on the Field device module Jumper X in position 1/2 No activation of the relay while the Fire Alarm Control Panel is in CPU failure mode (state on leaving factory).

Page 57: Technical Data Field Device Module

Fire Alarm Control Panel IQ8Control C/M 4.3.10 Technical data Field device module Operating voltage : Internal via the power supply module, +5 V DC / + 12V DC Quiescent current : approx. 15 mA @ 12 V DC Fuse F1 T1A –..Page 58: Extension Module

Fire Alarm Control Panel IQ8Control C/M Extension module Depending on the module type up to three slots for micro modules are integrated on the Extension module. Connections are available for each micro module. The pin assignment of the eight screw terminals depends on the employed type of micro module.Page 59: Technical Data Extension Module

Extension module. In this case the integration of an Field device module is impossible. In this case mounting of the field device is not possible anymore (refer to section „Panel configuration IQ8Control C“). Extension module with a single micro module slot (Part No. 772478) This Extension module must be configured in the panels data programming as a Field device module.- Page 60 Fire Alarm Control Panel IQ8Control C/M Notes FB 798951.GB0 / 01.09..

- Page 61 Installation Instruction Fire Alarm Control Panel IQ8Control C/M Micro modules 798951.GB0 G 299044 Technical changes reserved! 01.2009 G 205129 © 2009 Honeywell International Inc.

Page 62: Micro Module

Fire Alarm Control Panel IQ8Control C/M Micro module The FACP IQ8Control C / M has a modular design, so that micro modules can be replaced/extended at any time. Only remove or insert micro modules when the FACP is voltage free.- Page 63 Fire Alarm Control Panel IQ8Control C/M Mode of analog loop operation ® ® The esserbus PLus is a monitored two-wire loop fed from two sides and exhibiting loop topology. /esserbus The use of zone isolators allows you to combine ring and spur loops as well as divide the analog loop into 127 ®..

Page 64: Esserbus

Fire Alarm Control Panel IQ8Control C/M ® 5.1.1 esserbus Analog loop module (Part No. 784382 / 784382.10 / 784382.D0) ® The analog loop module enables you to connect the analog loop - the esserbus . The analog loop is configured with Programming software tools 8000 from index V1.06R001.Page 65: Esserbus ® -plus Analog Loop Module (part No. 804382 / 804382.10 / 804382.d0)

Fire Alarm Control Panel IQ8Control C/M ® 5.1.2 esserbus -PLus Analog loop module (Part No. 804382 / 804382.10 / 804382.D0) ® This module provides the 'esserbus PLus' loop mode, e.g. for direct connection of audible loop devices. Note ® that the esserbus PLus operation requires special components and panel settings.- Page 66 Fire Alarm Control Panel IQ8Control C/M ® The esserbus PLus cable is directly connected to the terminals on analog loop module (Part No. 804382 / 804382.10 / 804382.D0) Example: ® esserbus PLus cable terminal ⇒ Analog loop module (Part No. 804382 / 804382.10 / 804382.D0)

- Page 67 Fire Alarm Control Panel IQ8Control C/M ® 5.1.2.1 esserbus PLus alarm devices ® Available loop alarm devices for directly connection to the esserbus PLus analog loop. Part No. Name Load factor (LF) Fire detector IQ8Quad 802383 Visual 802384 Audible 802385, 802385.SVxx Visual + audible + speech 802386, 802386.SVxx..

Page 68: Technical Data Analog Loop Module

The permitted loop length depends on the number and type of the loop devices and may differ from the max. loop length. • max. 2 analog loop modules Part No. 804382 / 804382.10 / 804382.D0 per IQ8Control C as well as max. 4 or 6 modules per IQ8Control M ®..Page 69: Essernet ® Module

Fire Alarm Control Panel IQ8Control C/M ® essernet module ® ® The essernet module permits networking up to 31 essernet devices, such as e.g. Fire Alarm Control Panel System 8000 and IQ8Control, Intruder alarm panel system 5000 and WINMAG supervisor system software.Page 70: Essernet ® Micro Module (part No. 784840 / 784840.10 And 784841 / 784841.10)

Fire Alarm Control Panel IQ8Control C/M ® 5.2.1 essernet micro module (Part No. 784840 / 784840.10 and 784841 / 784841.10) ® The essernet micro module must be placed on the micro module slot of the Basic module. There for it is ®..- Page 71 Fire Alarm Control Panel IQ8Control C/M Rotary address switch to select panel address factor x1 Rotary address switch to select panel address factor x10 64 pin connector for the micro module slot inside the FACP X4 / X5 jumpers for configuration of the terminals IN/OUT (terminal 1+2 and 3+4)

Page 72: Technical Data Essernet ® Micro Module

Fire Alarm Control Panel IQ8Control C/M ® 5.2.2 Technical data essernet micro module ® ® essernet micro module 62.5 k essernet micro module 500 k (Part No. 784840 / 784840.10) (Part No. 784841 / 784841.10) Operating voltage : Internal via the power supply module,..- Page 73 Fire Alarm Control Panel IQ8Control C/M ® Setting the essernet address The address of Network Micro Modules type 1 and 2 with hardware revision E and higher is set as a decimal number by means of two rotary switches. Use an appropriate screwdriver for setting switches S1 (x1) and S2 (x10).

- Page 74 Fire Alarm Control Panel IQ8Control C/M ® Important installation instructions of essernet micromodules ® • The outgoing and return line of the essernet link must always be installed separately, i.e. not in a multiple- pair cable or cable duct. Installing them together may impair operation or, in the event of irreparable damage to the cable/cable duct, lead to failure of the connection because of a break in the outgoing and return line.

Page 75: Essernet

Fire Alarm Control Panel IQ8Control C/M FOC converter (Part No. 784763 / 784764) The FOC converter is used to convert electrical into optical signals for reliable data communication under difficult conditions e.g. where conventional copper cables are not suitable. Mixed operation of fibre optical and conventional wiring within a common network is possible.Page 76: Relay Module

Fire Alarm Control Panel IQ8Control C/M Relay module 3-relay module / 3-relay common trouble module Micro module for activating external devices (not potential free) such as a flashing lamp or siren, with monitoring capability. You may connect up to three external devices to this micro module.- Page 77 Fire Alarm Control Panel IQ8Control C/M Adjustment of the relays Relay Status Contacts switch S 1 Contact 10 k Ω monitored closed not monitored open 10 k Ω monitored closed not monitored open 10 k Ω monitored closed not monitored open No AC voltages may be applied to the relays built-into the Fire Alarm Control Panel.

- Page 78 Fire Alarm Control Panel IQ8Control C/M Wiring an external signalling device without loop monitoring Example with relay K2 (terminal 5 and 6), non-monitored mode alarm Fig. 65: Schematic wiring of an external signalling device without loop monitoring L = inductive load relay = series diode BY251 (notice relays current max.

- Page 79 Fire Alarm Control Panel IQ8Control C/M Connecting an external signalling device with loop monitoring Monitored activation of external devices involves monitoring the loop for an end-of-line resistor of 10 k Ω . In the event of an incident, polarity changes between monitoring and activation voltage at the (relay) connection terminals.

- Page 80 Fire Alarm Control Panel IQ8Control C/M Application examples (A) Three relays with a common external voltage (default setting). This application involves feeding an external voltage (e.g. +12V) to terminals 3 and 4 on the terminal card, this voltage then being switched via the relay to the external device for activation in the event of an incident occurring.

Page 81: 4- Relay Module

Fire Alarm Control Panel IQ8Control C/M 4- Relay module This micro module accommodates four freely programmable, non-monitorable, potential-free relays for activating external devices and system components. Relay assignment is programmed with the service PC and programming software tools 8000 from version V1.06R001 software.- Page 82 Fire Alarm Control Panel IQ8Control C/M Terminal card assignment ext. device at relay K1 ext. device at relay K2 ext. device at relay K3 ext. device at relay K4 Fig. 71: Terminal card assignment Schematic circuit diagram (example using relay K1) Pow er supply Fig.

Page 83: Technical Data Relay Module

Fire Alarm Control Panel IQ8Control C/M 6.2.1 Technical Data Relay module 4-relay module (Part No. 787530) Operating voltage : Internal via the power supply module, + 5 V DC / +12 V DC Quiescent current : approx. 10 mA @ 12 V DC..Page 84: Serial Interface Module

Fire Alarm Control Panel IQ8Control C/M Serial interface module 6.3.1 RS 232 / TTY module This module provides either a serial RS 232 or TTY interface (20mA) for exchanging data with external devices connected. Assignment of the serial interface type is programmed with the service PC and software tools 8000 from version V1.06R001 software.- Page 85 Fire Alarm Control Panel IQ8Control C/M Assignment of terminal card RS232 module external device not used TxD (transmitt) RxD (receive) not used not used not used Data Data GND (potential free) not used Fig. 75: Assignment of terminal card RS232 module Max.

Page 86: Technical Data Interface Modules

Fire Alarm Control Panel IQ8Control C/M 6.3.2 Technical data interface modules RS 232/TTY module (Part No. 784842) Operating voltage : Internal via the power supply module, + 5 V DC / +12 V DC Quiescent current : TTY-mode approx. 55 mA @ 12 V DC RS232-mode approx.Page 87: Master Box Activation Module

Fire Alarm Control Panel IQ8Control C/M Master box activation module Micro module for activating a master box (MFAB) and alerting the relevant emergency services, such as the fire department. With the Fire Alarm Control Panel, a connection for a master box module is integrated in the Field device module.- Page 88 Fire Alarm Control Panel IQ8Control C/M DIL switch S2 The time for the duration of the activation of the MFAB can be selected using DIL switch S2. Selecting the activation time for the MFAB activation for approx. 6 seconds activation for approx. 2,5 seconds This selection only becomes active when 'intermittent activation'..

- Page 89 Fire Alarm Control Panel IQ8Control C/M Wiring of the terminal card + MFAB supply voltage not use MFAB MFAB reset (+12 V or +24 V / 300 mA) (schematic circuit diagram) monitoring primary loop to MFAB (+MFAB) MFABrelay unlock fire department box (switched to GND max. 300 mA)

- Page 90 Fire Alarm Control Panel IQ8Control C/M Inhibiting MFAB activation The master box or master box relay will not be activated if, • the cover contact (lock on outer hosing) is open. (factory setting of solder jumper on module: BR2 = open ;..

Page 91: Technical Data Master Box Activation Module (part No. 784385)

Fire Alarm Control Panel IQ8Control C/M Technical Data Master box activation module (Part No. 784385) Operating voltage : Internal via the power supply module, + 5 V DC / +12 V DC Quiescent current consumption : approx. 10 mA @ 12 V DC (without monitoring) approx.- Page 92 Fire Alarm Control Panel IQ8Control C/M Overview – micro module terminals Basic module IQ8 Control 1 2 3 4 5 6 7 8 micro module Fig. 79: Overview – micro module terminals 3 4 5 ® Analog loop module esserbus (Part No.

- Page 93 Fire Alarm Control Panel IQ8Control C/M RS232 / TTY module (Part No. 784842) 3 4 5 Serial interface, alternatively RS232- or TTY (20 mA) to connect external devices e.g. WINMAG, Printers, Remote indicator panels etc. not used TxD (transmitt) RxD (receive)

- Page 94 Fire Alarm Control Panel IQ8Control C/M 4 Relay module (Part No. 787536) Four dry relay contacts (not monitored) with programmable 3 4 5 operation mode normally open or normally close. Contact rating: max. 30 V DC / 1A Quiescent current: approx. 10 mA.

- Page 95 Installation Instruction Fire Alarm Control Panel IQ8Control C/M Commissioning / Maintenance 798951.GB0 G 299044 Technical changes reserved! 01.2009 G 205129 © 2009 Honeywell International Inc.

Page 96: Installer Level

>Installer< in the Fire Alarm Control Panel IQ8Control C/M. The service level is protected from unauthorised access by a numeric authorisation code. This authorisation code is dependent on the >country function<..- Page 97 Fire Alarm Control Panel IQ8Control C/M The function menu of the installer level appears with four menu points: The function menu of the installer level with its four menu points appears after the successful entry of the authorisation code: Installer..

- Page 98 Fire Alarm Control Panel IQ8Control C/M Primary loop function Primary loop function Under this menu point, the internal primary loops of this Fire Alarm Control Panel or other Fire Alarm Control in ® an essernet network can be switched on or off and checked by a manual test function. Additionally, it is possible to replace single detectors in operative analog loops e.g.

- Page 99 Fire Alarm Control Panel IQ8Control C/M Testing (the analog loop) 1 Switch on / reset Primary loop / transfer route 2 Switch off Primary loop : 121 3 Test 4 Replace detector Escape Function Fig. 83: Testing the analog loop •..

- Page 100 Fire Alarm Control Panel IQ8Control C/M Detector replacement Replacement of fire and diagnostic detectors (4-zone module) Diagnostic fire detectors can be replaced without adjustment of the detector address on the base circuit board or overwriting data with the service PC. The menu options >Detector replacement< is inoperable for these detectors.

- Page 101 St : 080 the converse. ® Replacement of a manual call point with an esserbus transponder and St : 080 the converse. Operation without Service-PC available in the installer level of the Fire Alarm Control Panel IQ8Control C/M. FB 798951.GB0 / 01.09..

- Page 102 Fire Alarm Control Panel IQ8Control C/M Simulation of detector states ® Under this menu point, the state of addressable detectors of the series 9100, 9200 and IQ8Quad (no esserbus transponder) can be simulated for test purposes. In all non-addressable detectors (Series 9000), the detector zone state is simulated.

- Page 103 Fire Alarm Control Panel IQ8Control C/M Simulation of control states Under this menu point, the state of any control, such as relays or open collectors, can be simulated for test ® purposes. The simulation of control states in an essernet network is impossible.

- Page 104 Fire Alarm Control Panel IQ8Control C/M Query of additional and info texts of other control panels (remote text) With this function, the programmed additional and info text for controls, detector zones or detectors of any Fire ® Alarm Control Panel in the essernet network can be queried and shown on the display.

- Page 105 Fire Alarm Control Panel IQ8Control C/M Printer function Under this menu point, the protocol printer connected to the Fire Alarm Control Panel (internal printer and/or external serial printer) can be switched on or off. In addition, the contents of the internal event memory of the control panel can be printed out on a local protocol printer.

- Page 106 Fire Alarm Control Panel IQ8Control C/M Switching on the protocol printer Printer Switch off : 0110 Printer Switch on Print event mem Func.menu Repeat Select Fig. 92: Entering the number of the external (serial) printer • Enter the number of the printer which is to be switched on and press the >Select< function key.

- Page 107 Fire Alarm Control Panel IQ8Control C/M Display of the event memory At the installer level, the event memory of the Fire Alarm Control Panel can be shown on the control panel display by pressing the >Event mem< key. The last 200 events, such as alarms, malfunctions, switch-offs and operating authorisations are stored in the event memory in chronological order.

Page 108: Diagnostic Display

The diagnostic display enables, e.g. a fast check of the power supply values of this Fire Alarm Control Panel for service and maintenance work. In the control panel IQ8Control C/M display, a diagnostic field with individual measured values (analog measurement channels) which are automatically determined by the control panel is displayed.- Page 109 Fire Alarm Control Panel IQ8Control C/M ® The essernet diagnostic line ® The essernet connection of the various units in the network can be checked with this diagnostic line. ® The essernet diagnostic line (L:xxx) indicates which connections are functioning correctly and which have malfunctioned.

- Page 110 Fire Alarm Control Panel IQ8Control C/M ® Checking the essernet devices and connections ® ® An additional check of the essernet devices/connections can be carried out using the essernet micro modules (from index “E” onwards). Switching on the display on the fire alarm control panel:..

- Page 111 Fire Alarm Control Panel IQ8Control C/M ® Example of essernet diagnostic line with four Fire Alarm Control Panels ® In the illustrated example, four Fire Alarm Control Panels are interconnected in the essernet Panel No. 1 Panel No. 4 Panel No. 2 essernet ®..

- Page 112 Fire Alarm Control Panel IQ8Control C/M Display of the analogue values For service and maintenance work, the current analogue values for all micro modules and components of the device module can be displayed to check the FACP. The following tables show the individual micro modules, each with the valid range of analogue values.

- Page 113 Fire Alarm Control Panel IQ8Control C/M * 3 relay module/3 relay module CF Analog Normal value range FACP Function channel IQ8Control Ana 1 Relay 1 93 .. 141 Ana 2 Relay 2 93 .. 141 Ana 3 Relay 3 93 .. 141..

- Page 114 Fire Alarm Control Panel IQ8Control C/M * Master box, internal (device module) Analog Normal value range FACP Function channel IQ8Control Ana 1 Monitoring input, master box (K1) 14 .. 185 Ana 2 Not occupied Ana 3 Not occupied Ana 4..

Page 115: Meaning Of The Three Digit Error Codes / Test Mode

Fire Alarm Control Panel IQ8Control C/M Meaning of the three digit error codes / test mode A three digit error code is displayed in the alphanumeric display in case of a failure of an intelligent fire detector. The meanings of these codes and measures for correcting the error condition are given in the following table.- Page 116 Fire Alarm Control Panel IQ8Control C/M Trouble Possible cause 1st. measure 2nd. measure Code No. Check the installed detector if the surrounding area is humid. Use protective Clean detector and check it with measures if necessary, e.g. programming software tools Detector is soiled or damp.

- Page 117 Fire Alarm Control Panel IQ8Control C/M Trouble 2nd. measure Possible cause 1st. measure Code No. Detector unable to correctly Check detector base wiring. activate its base circuit board. Fault occurs while loop is being switched on: switch off loop and switch back on again after 1-2 minutes.

- Page 118 Fire Alarm Control Panel IQ8Control C/M Trouble Possible cause 1st. measure 2nd. measure Code No. Check whether the external ® esserbus transponder has switching voltage of the identified fault with its external ® esserbus transponder is in voltage. the correct voltage range.

- Page 119 Fire Alarm Control Panel IQ8Control C/M Trouble Possible Cause 1st. measure 2nd. measure Code No. If this change is not desired, There are more detectors on the connect service PC and run loop than programmed in the a configuration check. Re- customer data.

- Page 120 Fire Alarm Control Panel IQ8Control C/M Trouble Possible Cause 1st. measure 2nd. measure Code No. Check if the detector type The IQ8Quad detector circuit has change is desired; if yes, Otherwise, install desired been changed at the detector reprogram the customer data detector and restart location.

- Page 121 Fire Alarm Control Panel IQ8Control C/M 10.1 Trouble messages in the display Up to three works-programmed trouble messages with 8 characters each can be displayed in the second line of the display. If a clear text trouble message applying to an event is displayed, this trouble message is shown automatically in the display or can be activated with the function key >Param/AT<.

- Page 122 Fire Alarm Control Panel IQ8Control C/M Trouble Possible cause 1st. measure 2nd. measure text An error has been detected Localise the source with when an analog loop was programming software tools start-up switched on; normal operation 8000 switch on or reconfigure is impossible.

- Page 123 Fire Alarm Control Panel IQ8Control C/M Trouble Possible cause 1st. measure 2nd. measure text A dirty detector was found Clean or replace detector. int. det. err during an EDD zone test. A detector could not be reset Replace detector. reset during an EDD zone test.

- Page 124 Fire Alarm Control Panel IQ8Control C/M Notes FB 798951.GB0 / 01.09..

- Page 125 Installation Instruction Fire Alarm Control Panel IQ8Control C/M Options / Special applications 798951.GB0 G 299044 Technical changes reserved! 01.2009 G 205129 © 2009 Honeywell International Inc.

Page 126: Functionality For Fire Alarm Control Panels

Fire Alarm Control Panel IQ8Control C/M Functionality for fire alarm control panels The fire alarm control panel can be programmed to activate door control systems by installing an door control ® transponder. The esserbus door control transponder is operated as a bus device on the analog loop of the IQ8Control fire alarm system.Page 127: Iq8wireless Devices

Fire Alarm Control Panel IQ8Control C/M IQ8Wireless devices The IQ8Wireless devices provide the wireless connection of fire alarm detectors and alarm devices to the analog loop of the Fire alarm system IQ8Control or alternatively a stand-alone wireless control unit for fire alarm panels with conventional detector zone inputs.- Page 128 Fire Alarm Control Panel IQ8Control C/M 12.1 Important battery information Battery information relating to power consumption and batteries (Art. No. 805597) for use in IQ8Wireless RF components • Insert batteries into the RF devices shortly before initial operation (assigned to the RF transponders)! Unassigned RF devices consume approx.

Page 129: Top Hat Rail Mounting Kit (part No. 788652)

Top hat rail mounting kit (Part No. 788652) In the IQ8Control C/M FACP housing can be installed a top hat rail mounting kit (optional). This mounting kit comprises of a mounting base and a standard 35 mm top hat rail (C-mounting). In order to facilitate mounting and removal, the top hat rail is fitted to the mounting base by means of two screws.- Page 130 Remove one of this screws Carefully turn the top hat rail by 90° max. to remove it Fig. 105: Mounting/removal of the top hat rail mounting kit (FACP IQ8Control C/M) Always check that the connection cables are long enough! Ensure that no cables are pinched or damaged when installi ng or removing the assembly.

- Page 131 Fire Alarm Control Panel IQ8Control C/M ® esserbus transponder ® esserbus transponders are input/output modules for extending the control panel inputs/outputs. As devices on ® the analog loop - the esserbus - they may be operated jointly in separate detector zones with fire detectors on ®..

Page 132: Esserbus ® Transponder

Fire Alarm Control Panel IQ8Control C/M Extension housing Four different extension housings are available for individual extension of the FACP IQ8Control C/M Part No. Description 789300 Extension housing for batteries Housing complete with battery rear panel, space for two rechargeable batteries with an individual capacity of 12 V / 24 Ah.- Page 133 Fire Alarm Control Panel IQ8Control C/M The extension housing is assembled similar to the central housing. The individual assembly steps are described in the section 'Assembling the central housing'. The following must also be observed when assembling the extension housing: •..

Page 134: Extension Housing For Two Batteries (part No. 789300 / -01)

Fire Alarm Control Panel IQ8Control C/M 15.1 Extension housing for two batteries (Part No. 789300 / -01) Up to 2 batteries 12 V / 24 Ah may be placed inside the lower housing part of the IQ8Control M or in the extension housing (part no.Page 135: Power Supply For The Built-in Printer

Fire Alarm Control Panel IQ8Control C/M Power supply for the built-in printer The internal power supply of the built-in printer is provided by the basic module terminals of the FACP. +UBext. +UBext. +UBext T2A +UBext T2A Printer Printer +UBext. +UBext.Page 136: Mounting / Replacing Of The Panel Front + Printer

Fire Alarm Control Panel IQ8Control C/M Mounting / Replacing of the Panel front + Printer 17.1 Heat transfer Printer without paper take-up unit (Part No. 7868xx / 7869xx) Panel front for heat transfer Printer without paper take-up unit. Language identification, e.g. 00=German, 01=English etc.- Page 137 Fire Alarm Control Panel IQ8Control C/M Wiring FACP IQ8Control with Panel front (Part No. 7868xx) X23 Printer Basic module +UBext. +UBext T2A Printer switched +12 V ext. Ribbon cable Fig. 115: Wiring Printer Ribbon cable, length 50 cm (Part No. 750756) / Ribbon cable, length 120 cm (Part No.

- Page 138 Fire Alarm Control Panel IQ8Control C/M Wiring FACP IQ8Control with Panel front (Part No. 7869xx) Operating panel with 1/4 VGA Display (Part No. 7869XX) X23 Printer X24 MMI +UBext. +UBext T2A Printer Basic module Ribbon cable Ribbon cable switched +12 V ext.

Page 139: Printer With Paper Take-up Reel (part No. 7863xx)

Panel front with heat transfer printer with paper take-up reel. Panel front for heat transfer printer with paper take-up reel (Part No. 7863xx) and printer kit for IQ8Control C / M (Part No. 784792) Language identification, e.g. 00=german, 01=English etc.- Page 140 Fire Alarm Control Panel IQ8Control C/M Wiring FACP IQ8Control Basic module IQ8 Control X23 Printer +UBext. +UBext T2A Printer switched +12 V ext. Ribbon cable Fig. 122: Wiring Printer with paper take-up reel Customer data programming with tools 8000 The printer must be programmed with the tools 8000 programming software from Version 1.00 or higher as a >Printer with take up reel for Serial 2<..

Page 141: Fire Protection Housing (f30)

Fire Alarm Control Panel IQ8Control C/M Fire protection housing (F30) The fire protection housing (part no. 788030 = RO or part no. 788031 = LO) enables the installed fire alarm control panel (FACP) to maintain its function (fire resistance class F30). The manufacturer’s documentation enclosed in the fire protection housing (F30) must be observed when assembling and installing the FACP (warranty in accordance with manufacturer’s specifications, Priorit AG).- Page 142 Fire Alarm Control Panel IQ8Control C/M Fire protection housing (F30) with fire alarm control panel Fig. 124: Schematic diagram with installed FACP 8000/IQ8Control M Fire protection housing (F30) - RO or LO Ventilation system (optional) Mounting lugs (above + below)

- Page 143 Fire Alarm Control Panel IQ8Control C/M Pivoted lever closure • Turn the pivoted lever 90° upwards in an anti-clockwise Opening: direction • Open the door • Close the door, making sure that the pivoted lever is in the Closing: open position •..

- Page 144 Fire Alarm Control Panel IQ8Control C/M Sub-package Fire protection housing (F30) 1 x Fire protection housing (F30) – Part No. 788030 = RO or Part No. 788031 = LO 1 x Fire protection compound to seal housing openings 1 x Mounting material (frame anchors incl. screws 10 mm) Storage •..

- Page 145 Fire Alarm Control Panel IQ8Control C/M Notes FB 798951.GB0 / 01.09..

- Page 146 Novar GmbH a Honeywell Company Dieselstraße 2, D-41469 Neuss Telefon: +49 (0) 21 37 / 17-0 Verwaltung Internet: www.esser-systems.de +49 (0) 21 37 / 17-600 E-Mail: info@esser-systems.de Telefax: +49 (0) 21 37 / 17-286..